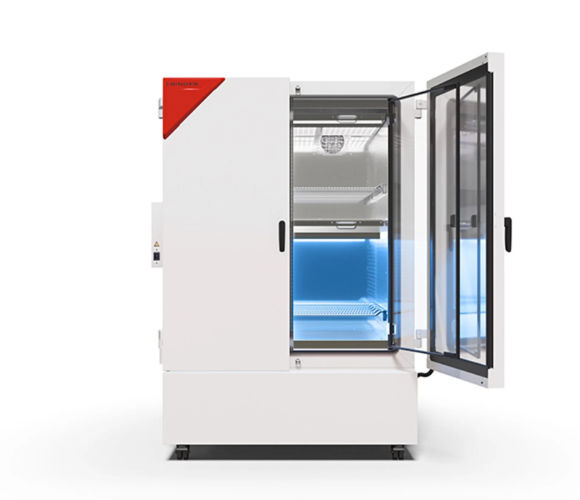

Constant Climate Chamber

A constant climate chamber, also known as a climate cabinet or climate chamber, is a unit used to simulate certain environmental conditions (temperature and relative humidity). Environmental simulation testing in climate chambers provides an indication of how test specimens will behave under defined climate conditions. The tests therefore ensure product quality and stability and give an idea as to their service life and durability. It is important that the units ensure homogeneous climate conditions in terms of time and space and that the climate conditions are documented continuously during the tests (data log functions for the temperature and humidity process parameters).

Applications:

⦿ ICH stability testing

⦿ Development of plant-based meat alternatives

⦿ Aging test in medical technology

⦿ Research

.

Photostability Test Chambers

A photostability test chamber is a climate chamber with light which generates defined light conditions in addition to temperature and humidity. Light climate chambers are used for stability testing to determine the shelf life of products. They are used in different sectors, such as the pharmaceutical, cosmetics, and food industries. Photostability tests examine the influence of temperature, humidity, and exposure to light on a product. The test materials are first stored in a climate chamber under defined conditions (constant temperature, constant relative humidity, and constant light intensity) for a specified period of time before the shelf life is checked. The test materials are exposed to light using both visible light (VIS) and ultraviolet radiation (UV), which is considerably more aggressive than VIS radiation.

Applications:

⦿ Photostability Tests According to Guideline ICH Q1B

⦿ Accelerated Shelf-life Testing in the Food Industry

.

Plant Growth Chambers

A plant growth chamber is an enclosed climate chamber which generates a defined climate (temperature and humidity) and defined light conditions. In addition, a defined CO2 concentration may be useful or necessary.

In contrast to walk-in plant growth chambers (phytotrons) or greenhouses, isolated experiments can be carried out in plant growth chambers under precisely defined and reproducible conditions.

Providing the basis for BINDER plant growth chambers are climate chambers from the KBF and KBF PRO series with temperature and humidity control as well as refrigerated incubators from the KB PRO series. These basic units are equipped with retrofittable LED plant light modules: The control unit is attached to the exterior using supplied fastening elements and the LED strip lights are secured in the interior of the units as required using metal clips.

Applications:

⦿ Agriculture, agrobiology

⦿ Horticulture, fruit farming, winemaking, cultivation of ornamental plants

⦿ Green genetic engineering

⦿ Phytobiology, photobiology

⦿ Plant physiology and plant genetics

⦿ Plant protection, plant health

⦿ Entomology

.

Dynamic Climate Chambers (for rapid temperature changes)

BINDER environmental simulation chambers don’t fail to impress with their high precision and performance levels. They are perfectly suited to material testing under dynamic conditions, with these dynamic climate chambers meeting current IEC, MIL, and EN standards and making it easy to generate even the most complex of climate profiles.

Varying depending on the series and model, the environmental simulation chambers operate within a temperature range of -40 °C/-70 °C and 180 °C. The climate chambers in the MKT and MKFT series can also control the humidity levels within a range of 10 to 98% RH.

It takes almost no time at all for BINDER environmental simulation chambers to simulate various climate conditions, including the extremes. This makes it possible to run accurate tests to see how test specimens react to different environmental conditions – crucial in the automotive, metallurgy, and aerospace sectors as well as other branches of industry.

Whether conditions are at the hot or cold extreme, environmental simulation chambers from BINDER can be relied upon for stress and stability tests, providing homogeneous temperature distribution across the entire testing area, even when fully loaded.